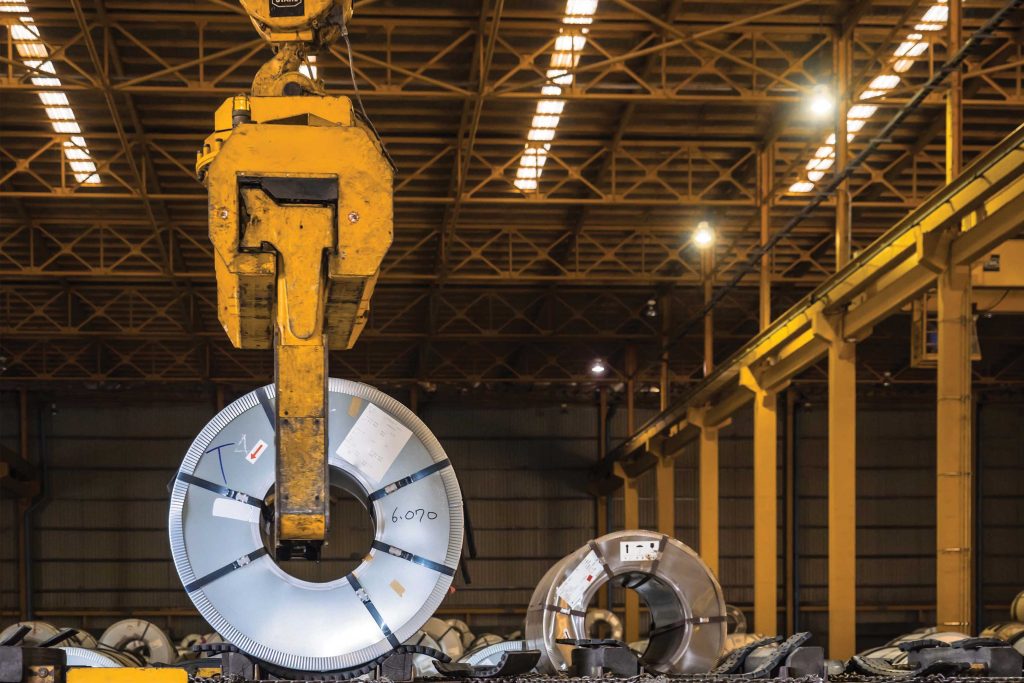

Galvanized Steel

The most common method is hot-dip galvanizing, in which parts are submerged in a bath of molten zinc. Some of the applications for galvanized steel coils/sheets:

Galvalume Coated

A steel with a coating layer made from almost 55% aluminum & 45% zinc.

Galvalume is recommended when a high level of corrosion resistance is important:

Applications include:

- pre-engineered metal buildings

- industrial roofing and siding

- air-conditioning equipment

- building panels

- electrical boxes

- farm equipment & machinery

- furnace parts

- guide rails

- heating equipment & appliances

Prepainted Galvanized

A steel with double protective layers of paint and zinc, where the steel is painted before forming.

It is widely used in:

- construction

- home appliances

- furniture

- utilities

- transport

Electrogalvanized Steel

Electrogalvanized steel is manufactured by electroplating a pure zinc coating on one or two sides.

In addition, the coated surface has a smooth, matte appearance.

Thus, the surface quality is exceptionally good for applications that require a high finish after painting, such as automotive exposed panels.